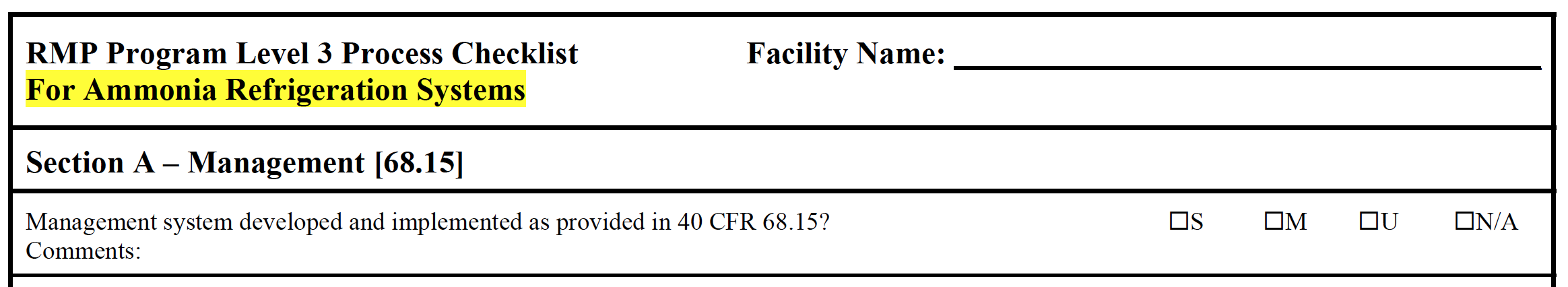

EPA's RMP Program Level 3 Process Checklist For Ammonia Refrigeration Systems

Many thanks to my friends at EPA (and OSHA) for sharing this EPA RMP Checklist specific to Ammonia Refrigeration Processes. Here are the "highlights" specific to NH3 processes. It should be noted that this RMP Checklist specific to Ammonia Refrigeration Processes was developed in conjunction with the International Institute of Ammonia Refrigeration (IIAR) and all EPA Regions. NOTE: SAFTENG members can download the Entire Checklist in pdf inside the Chemical Process Safety - Document Library) |

Partner Organizations I am proud to announce that The Chlorine Institute and SAFTENG have extended our"Partners in Safety" agreement for another year (2024) CI Members, send me an e-mail to request your FREE SAFTENG membership

Member Associations

|