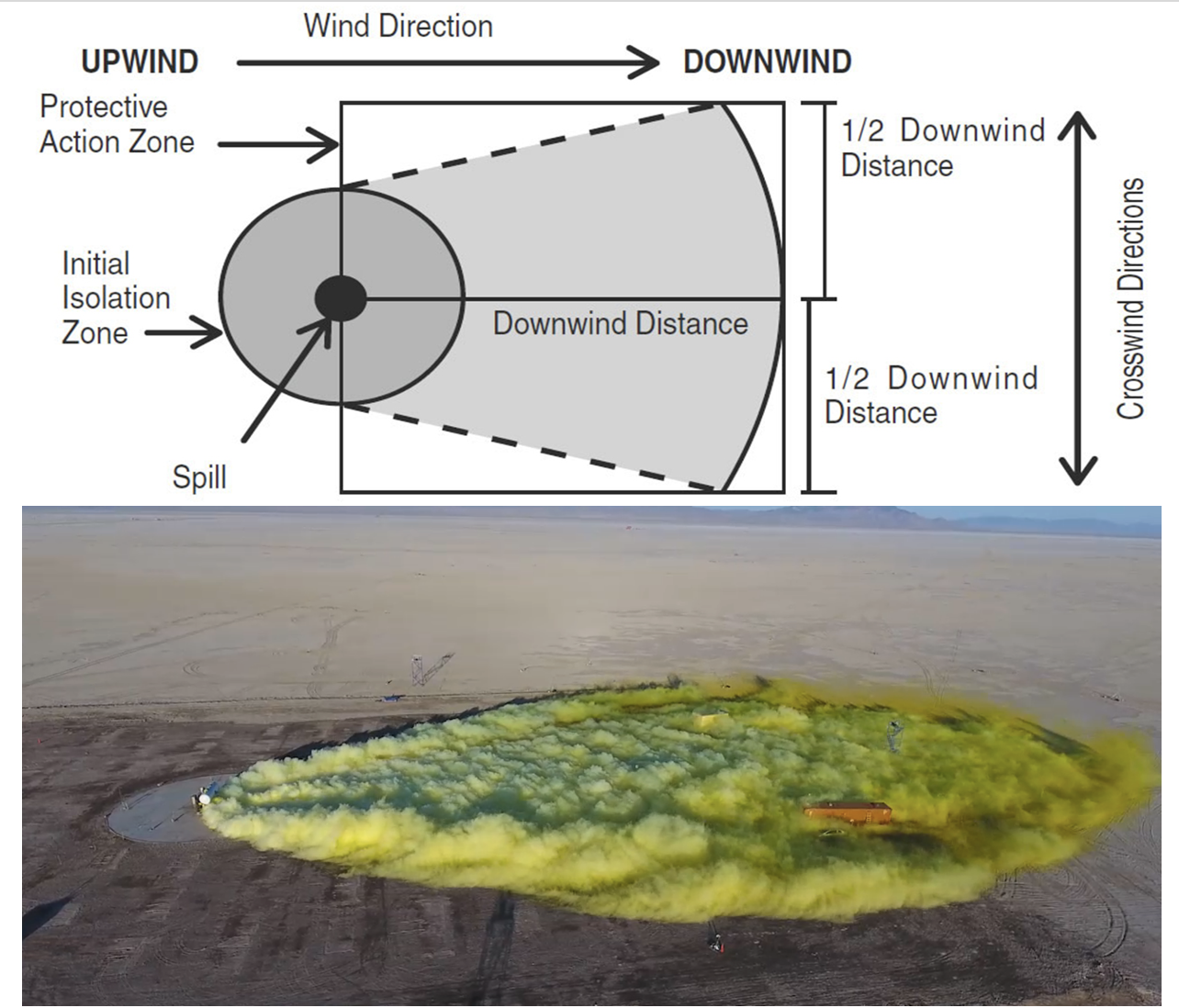

The Protective Action Distance makes sense when you see this

An image from my HAZMAT courses... People wonder why the ERG Protective Action Distance diagram is shaped like it is. This image validates the model...

NOTE: Cl2 release image is from the Jack Rabbit testing project Add new comment

Human Factors in incident investigations assessment tool

Here is a GREAT "self-assessment" tool, just eight (8) questions, to evaluate your facility's ability to investigate and perform causal analysis properly. Appeals Court sides with Paper Mill over Confined Space incident

This is a crazy case! The mill hired a contractor to build scaffolding inside one of its Chlorine Dioxide (CLO2) tanks. The mill prepped the tank and even performed the initial air sampling of the space. Turned it over to one of the scaffolding contractor employees who would be the attendant for the entry. Three entrants and the attendant were wearing personal Cl2 air monitors. Three scaffolding builders entered the tank. After 30-40 minutes, one of them felt ill and exited the tank. Once outside his personal detector alarmed. Soon after, the other two workers' detectors went into alarm, and they exited the tank. Two entrants were hospitalized for two (2) days; the other two were treated and released. The employee who filed the suit continued to suffer symptoms from chlorine dioxide exposure, including excessive coughing and wheezing. He was diagnosed with bronchiolitis obliterans and upper airway injuries. He sued the mill, the company that made the personal detectors, and the company that supplied the detectors. So far, he has lost his case. This was his appeal, but it did not go well. The paper mill claimed they had no control over the event, even though it was their tank on their property. This post is NOT about limiting liability but about managing PRCS entry hazards. I will note that the meters' manufacturer presented evidence that two of the monitors detected chlorine dioxide limits that would have put them into alarm, but the monitors were switched off less than two minutes later. This happened several times over 24 minutes for one monitor and 33 minutes for the other. As noted above, their final inspection of the monitors before they were sold to the rental company had low alarm settings at 0.10 ppm and high alarm settings at 0.20 ppm. By the time of the incident, the settings had been changed to 0.20 ppm and 0.50 ppm. Safway employees stated that they had not changed the settings. The presumption is that the rental company changed them. Here is all the legal wrangling! OSHA finds Florida contractor ignored federal safety measures that could have prevented welder’s confined space fatality (O2 Deficiency)

As he had many other days, the morning shift welder arrived at 5 a.m. to work on Aug. 28, 2023. Tasked with doing some fabrication work in a 4-foot by 8-foot space in a ship’s hull, the employee began work unaware that fatal suffocation would soon end his life. Less than two hours after entering the ship, a supervisor found the unconscious welder and signaled for help, only to fall unconscious as well. A third employee appeared, alerting EMS and the local Fire Department, who soon transported all three workers to a nearby hospital. Despite emergency treatment, the welder died from a lack of oxygen. The supervisor and the third worker received medical treatment and were released. OSHA CSHOs determined the employer exposed workers to oxygen deficiency by sending the welder into a confined space without testing the air for oxygen content. The presence of welding gas in the space created an oxygen-deficient atmosphere. OSHA investigators found that in addition to a lack of oxygen, the shipbuilder also exposed workers to struck-by and crushing hazards by failing to conduct annual inspections of six cranes. The agency cited the company with four serious violations and has proposed $55,539 in penalties, an amount set by federal statute. The company has contested the findings before the independent Occupational Safety and Health Review Commission. Citations are below... Comparison of Tier II, TRI, and 112(r) Requirements (TCEQ)

The Emergency Planning and Community Right-to-Know Act (EPCRA) requires businesses that store and/or manufacture, process, or use certain chemicals to complete the Tier II (EPCRA 311 and 312) Report and/or the Toxics Release Inventory (EPCRA 313) Report, also called the Form R. Section 112(r) of the Clean Air Act focuses on risk management for accident prevention. While these three (3) programs have similar reporting elements, they have significant differences outlined in the following table. How do you differentiate between an amputation without bone and avulsions?

How do you differentiate between an amputation without bone and avulsions? Portable Fire Extinguishers Standard (Annual Maintenance Certification Record)

Paragraph (e)(3) of the 1910.157 specifies that employers must subject each portable fire extinguisher

In addition, this provision requires employers to retain the inspection record for

and to make the record available to OSHA on request. This recordkeeping requirement assures workers and agency compliance officers that portable fire extinguishers located in the workplace will operate normally in case of fire; in addition, this requirement provides evidence to OSHA compliance officers during an inspection that the employer performed the required maintenance checks on the portable fire extinguishers.

Its the little things that matter... open top or bung top container

And I will bet someone will suggest a closed-top/bung-style container. Keep in mind that this is NOT preventing the event/failure that makes a bung top drum a safety device, but it could be a protection layer and most certainly would be considered a mitigation layer should we have an eruption from the container. When using the bung style drum, remember to ALWAYS have it vented so as to not "launch" the drum, making it a hazard. We always used the 2" bung for our hose/sparger and the 0.5" bung for our "vent". These bung drums also slow the liberation of gas/vapors from our absorbent material (usually water or caustic). So give it some consideration; it may just be the ticket for those unexpected "surges" caused by improper energy isolation or blockage breaking free in the piping. The same application is used for 5-gallon containers such as "draining oil" from a refrigeration "oil pot" where sputtering is not uncommon. But remember, VENTING is critically important. We can lay a rag over the vent to reduce splash/sputter from the opening; it can also help reduce odors and off-gassing - BUT NEVER BLOCK the vent with any mechanical device or leave it plugged/closed.

PRCS Fatality (O2 Deficiency)

At 5:00 p.m. on September 20, 2023, an employee entered an oil well production tank to replace a leaking valve. The employee became unconscious when he entered the confined space. The employee died of asphyxiation in the hazardous atmosphere. Limitations of EH Rated Safety Footwear

This article aligns with my previous article, "When are High-Vis garments no longer considered High-Vis?" It is in the same spirit of managing the PPE that so many workers rely on daily. And anyone who has been in safety for six months or longer can tell us horror stories of what they have seen with workers wearing and claiming some PPE is "protecting them." Although OSHA does not require EH-rated safety footwear, many employers specify this rating for certain employees who may do "electrical work." If we specify that their safety footwear carries the EH (Electrical Hazard) designation, then should we not work to maintain that designation? First, what does it mean when safety footwear has the EH designation? Here's your sign... 1910.145

We visit 25-30 facilities each year, with about 15% of those being first-time and last-time visits! And man-o-man, we see some crazy things. I may have unreasonable expectations of safety, but complying with OSHA standards that have been on the books for 50+ years should not be a battle we are still fighting today. Take basic safety signage for example. The OSHA standard on accident prevention signs and tags (1910.145) has been around since 1974, and although a lot of facilities rely on these signs as reminders to work safely or to point out specific hazards, they are often made "in-house" and fall well short of complying with the OSHA standard and a far cry from the ANSI standards ANSI Z535 series. The number of facilities and their safety personnel who are not even aware of these fundamental requirements is shocking. Then, listen to their complaints regarding the Audit/Assessment findings about how "nit-picky" we are. Sayings like "that faded sign never hurt anyone" are astounding. It is a short and easy standard to read and understand. You don't need to attend an OSHA outreach course, hire a consultant, or spend a lot of time or money to get these basics under control. Let's start with the two (2) classes of signs OSHA prescribes: (emphasis by me) |

Partner Organizations I am proud to announce that The Chlorine Institute and SAFTENG have extended our"Partners in Safety" agreement for another year (2024) CI Members, send me an e-mail to request your FREE SAFTENG membership

Member Associations

|

I have written many articles discussing evacuating hazardous materials from a piping system. Over my career, I learned that using an open-top container can have disastrous results. It may sound silly or petty, but when something fails in the tasks and the hazardous material erupts from the open-top container, making contact with the worker(s), you will begin to ask... is there a better way?

I have written many articles discussing evacuating hazardous materials from a piping system. Over my career, I learned that using an open-top container can have disastrous results. It may sound silly or petty, but when something fails in the tasks and the hazardous material erupts from the open-top container, making contact with the worker(s), you will begin to ask... is there a better way?