Flammable Liquids

On January 13, 2022, workers inside the company’s fabrication shop performed a "wet test" on a newly built tank truck to check for leakage. This entailed running diesel test fuel through different tank compartments and other truck components. This was a routine operation at the workplace. Workers knew never to use gasoline, and the company had a standard operating procedure that prohibited gasoline or any tanker truck containing gasoline from entering the fabrication shop. The diesel test fuel was stored in a tank outdoors. An Ontario Fire Marshall investigation found that the gasoline involved in the explosion resulted from the use of CONTAMINATED diesel test fuel in the "wet test." Membership Content

I have written several articles on the topic of when we store our flammable liquids BELOW their flash points with the aid of refrigeration and how that makes our "refrigeration/chiller" a critical utility if we wish to take credit for storing the flammable below its FP. I have also discussed processing a Class IIIB/Cat 4 flammable liquid within 30 degrees of its FP. However, this article is about a "utility process" used for heating a process, and the heat transfer fluid (HTF) is heated above its FP. This process and analyzing its hazards can be tricky. When we look at the Safety Data Sheets and the Technical Datasheets, these fluids are almost always listed as "Non-Flammable" as their FPs are well over 200F. So at standard temperature and pressure (i.e., 68°F and 14.7 psi), the solution is indeed NOT flammable; however, we will be heating the solution to above its FP. This is a recognized hazard by OSHA, Insurance Providers, and NFPA; which insurance and NFPA 30 provide the user(s) some excellent DESIGN features to help PREVENT a LOPC event and PROTECTION and MITIGATION layers when the LOPC event occurs. First and foremost, codes and standards manage these hazards by setting a tolerance against operating up to 30 degrees within the solutions FP.

Are "safety cans" created equally? Nope, and which UL standard they meet will dictate how much "safety they provide." OSHA's 1910.106 defines a "safety can" as

NFPA has a slightly different definition:

Have you ever walked up to a atmopsheric storage tank and seen the paint bubbling and the hazard signs/placards faded/peeling off? Look up and you will most likely see the atmopsheric vent line on that side of the tank. What are these indicators of? The tank being over filled, which is a serious event and is certainly a Loss of Primary Containment (LOPC) event. But these days, these events should be a thing of the past, as the IFC and most state Fire Codes now require these flammable liquid Storage Tanks to have "Overfill" safety systems. (emphasis and revised structure by me)

NOTE: this unsafe practice can also have an impact on PSM/RMP coverage! Here is the OH Fire Code language (mimics the IFC) (emphasis by me)

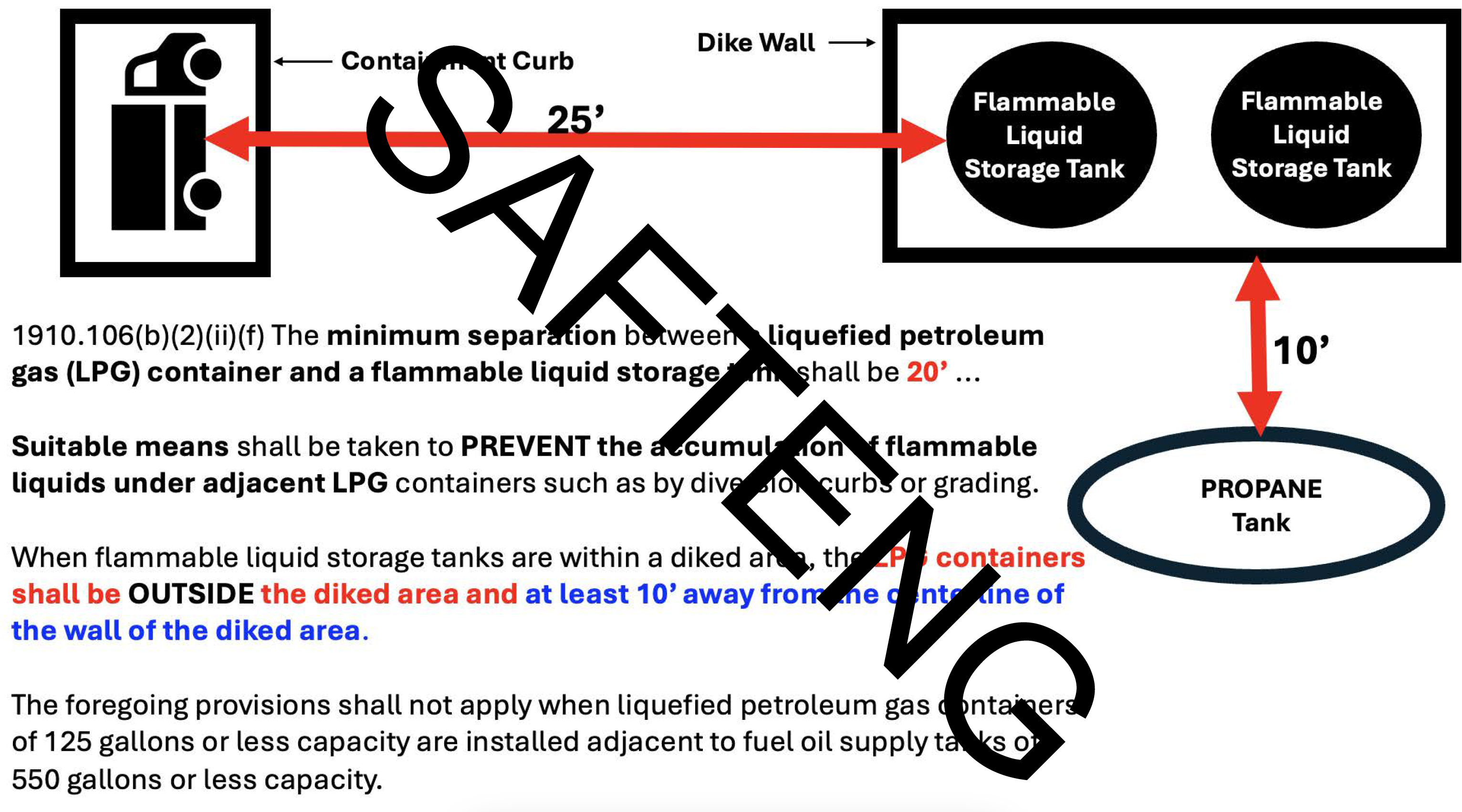

This is another opportunity for facility sitting to apply specific metrics to the exercise. Just as the distances for Tank Truck and Rail Car Unloading/Loading facilities are intended to protect our bulk storage tanks, this is intended to prevent BLEVE(s) that could impact the above-ground storage tank. (emphasis by me)

SAFTENG members can download the image depicting this requirement

|

Partner Organizations I am proud to announce that The Chlorine Institute and SAFTENG have extended our"Partners in Safety" agreement for another year (2024) CI Members, send me an e-mail to request your FREE SAFTENG membership

Member Associations

|

Although it is done often, most state Fire Codes PROHIBIT the use of DOT tank vehicles and tank cars as "Flammable Liquid Storage Tanks." We call this "dropping trailers," and my 2014 Article "

Although it is done often, most state Fire Codes PROHIBIT the use of DOT tank vehicles and tank cars as "Flammable Liquid Storage Tanks." We call this "dropping trailers," and my 2014 Article "