Permit Required Confined Spaces

This is a crazy case! The mill hired a contractor to build scaffolding inside one of its Chlorine Dioxide (CLO2) tanks. The mill prepped the tank and even performed the initial air sampling of the space. Turned it over to one of the scaffolding contractor employees who would be the attendant for the entry. Three entrants and the attendant were wearing personal Cl2 air monitors. Three scaffolding builders entered the tank. After 30-40 minutes, one of them felt ill and exited the tank. Once outside his personal detector alarmed. Soon after, the other two workers' detectors went into alarm, and they exited the tank. Two entrants were hospitalized for two (2) days; the other two were treated and released. The employee who filed the suit continued to suffer symptoms from chlorine dioxide exposure, including excessive coughing and wheezing. He was diagnosed with bronchiolitis obliterans and upper airway injuries. He sued the mill, the company that made the personal detectors, and the company that supplied the detectors. So far, he has lost his case. This was his appeal, but it did not go well. The paper mill claimed they had no control over the event, even though it was their tank on their property. This post is NOT about limiting liability but about managing PRCS entry hazards. I will note that the meters' manufacturer presented evidence that two of the monitors detected chlorine dioxide limits that would have put them into alarm, but the monitors were switched off less than two minutes later. This happened several times over 24 minutes for one monitor and 33 minutes for the other. As noted above, their final inspection of the monitors before they were sold to the rental company had low alarm settings at 0.10 ppm and high alarm settings at 0.20 ppm. By the time of the incident, the settings had been changed to 0.20 ppm and 0.50 ppm. Safway employees stated that they had not changed the settings. The presumption is that the rental company changed them. Here is all the legal wrangling! Read more ... Add new comment

As he had many other days, the morning shift welder arrived at 5 a.m. to work on Aug. 28, 2023. Tasked with doing some fabrication work in a 4-foot by 8-foot space in a ship’s hull, the employee began work unaware that fatal suffocation would soon end his life. Less than two hours after entering the ship, a supervisor found the unconscious welder and signaled for help, only to fall unconscious as well. A third employee appeared, alerting EMS and the local Fire Department, who soon transported all three workers to a nearby hospital. Despite emergency treatment, the welder died from a lack of oxygen. The supervisor and the third worker received medical treatment and were released. OSHA CSHOs determined the employer exposed workers to oxygen deficiency by sending the welder into a confined space without testing the air for oxygen content. The presence of welding gas in the space created an oxygen-deficient atmosphere. OSHA investigators found that in addition to a lack of oxygen, the shipbuilder also exposed workers to struck-by and crushing hazards by failing to conduct annual inspections of six cranes. The agency cited the company with four serious violations and has proposed $55,539 in penalties, an amount set by federal statute. The company has contested the findings before the independent Occupational Safety and Health Review Commission. Citations are below...

At 5:00 p.m. on September 20, 2023, an employee entered an oil well production tank to replace a leaking valve. The employee became unconscious when he entered the confined space. The employee died of asphyxiation in the hazardous atmosphere.

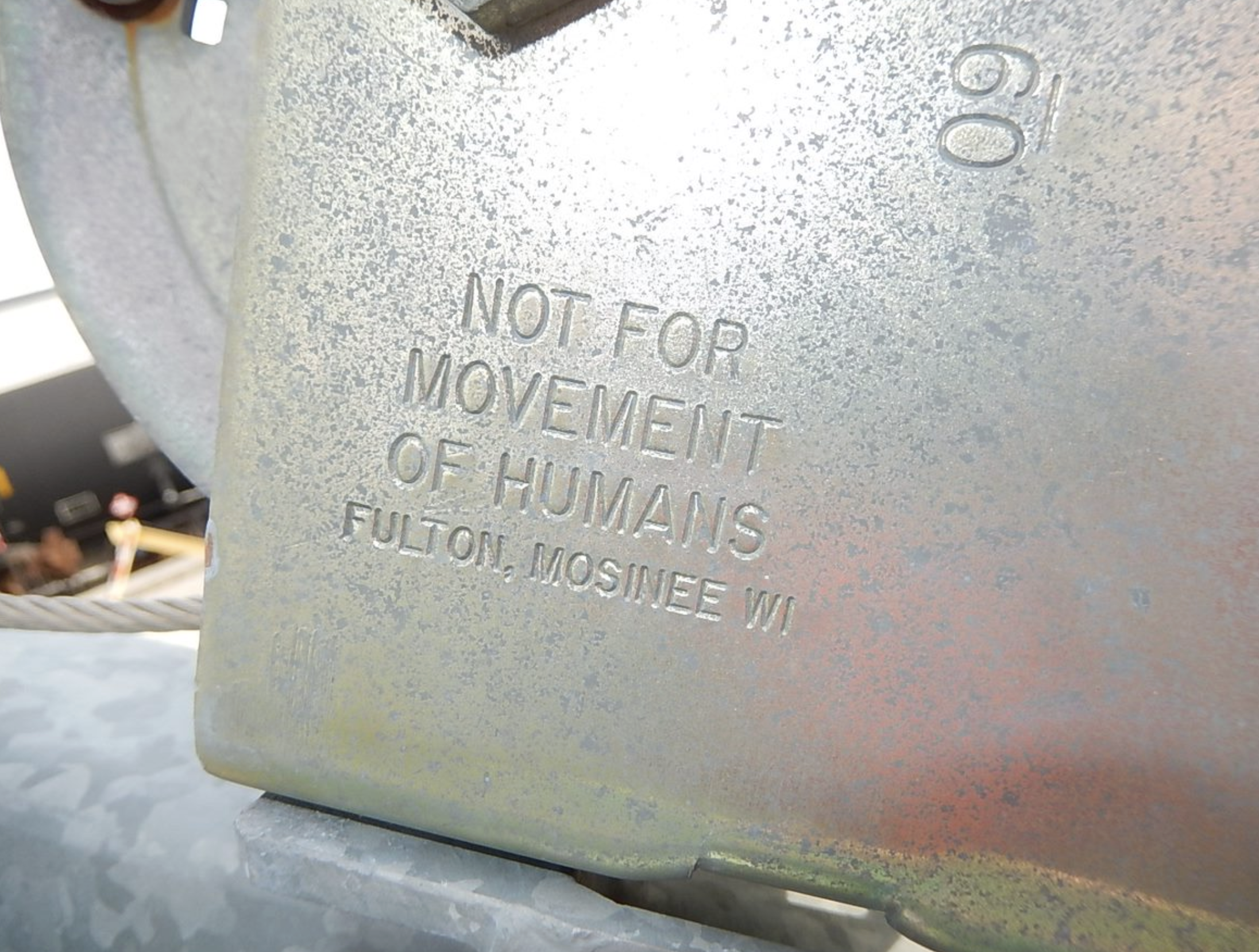

The mechanical device used for emergency rescue must be designed and rated for human use. The standard specifies in paragraph 1910.146(k)(3)(ii) that the retrieval equipment must be designed for personnel. The performance-oriented nature of the standard allows flexibility as to the design specifications of the retrieval equipment itself. OSHA accepts certification by manufacturers as well as listing (as being tested) by Nationally Recognized Testing Laboratory (NRTL). An employer may design, manufacture, test, and certify (for example by a registered professional engineer) mechanical devices used for retrieval of personnel from a vertical space.

|

Partner Organizations I am proud to announce that The Chlorine Institute and SAFTENG have extended our"Partners in Safety" agreement for another year (2024) CI Members, send me an e-mail to request your FREE SAFTENG membership

Member Associations

|

OSHA states the following about our non-entry rescue devices...

OSHA states the following about our non-entry rescue devices...