Hazardous Materials

There are two (2) types of Asphyxiants:

These different types of asphyxiants behave differently and cause harm differently.

SIMPLE Asphyxiants displace the 20.8% Oxygen in the atmosphere. These are NOT toxic or poisonous; they are called INERT gases. The most famous SIMPLE Asphyxiant is Nitrogen (N2). It is notoriously renowned as it has killed many workers inside and outside of confined spaces. Since 2020, there have been 14 fatal accidents involving N2 that claimed 26 lives. The most recent claimed Six (6) workers. I have written several articles referencing code requirements when asphyxiants are used in the workplace. Most states (all but six) have adopted some version of the International Fire Code (IFC), which is an excellent baseline for designing systems handling these inert gases and the atmospheric monitoring systems REQUIRED in areas where these asphyxiants are stored, handled, and processed. It takes very little of these gases to create a HAZ ATM (e.g., Oxygen-Deficient). Most of these simple asphyxiants have NO WARNING properties, meaning we can not smell, taste, hear, or feel their presence. A room/space at 20.8% O2 only needs to lose 1.3% of its O2 before we have an IDLH atmosphere. Without proper mechanical exhaust ventilation and/or an atmospheric monitoring system, workers can be overcome quickly. NOTE: another simple asphyxiant gaining popularity without proper safeguards is Carbon Dioxide (CO2). We are seeing Liquid Dewars of CO2 being used in the resturant industry for softdrinl machines as well as its use as a refrigerant in industrial refrigeration systems.

CHEMICAL/SYSTEMIC Asphyxiants work their harm differently. The atmosphere could have adequate Oxygen levels, but once we inhale these chemical/systemic asphyxiants, the hemoglobin in our blood has an affinity for these gases over that of the Oxygen. So these gases attach to our red blood cells/hemoglobin rather than the O2, and we "suffocate" in an adequate supply of O2. Carbon Monoxide is probably the most famous Chemical/Systemic asphyxiant. When we hear of a death by "smoke inhalation," this was a CO-poisoning death. When carbon monoxide is inhaled, it combines with hemoglobin (an iron-protein component of red blood cells), producing carboxyhemoglobin (COHb), which greatly diminishes hemoglobin's oxygen-carrying capacity. Hemoglobin's binding affinity for carbon monoxide is 300 times greater than its affinity for oxygen. (Source: NIOSH) Since 2022, there have been 20 fatal accidents involving CO, claiming 24 lives. Read more ... Add new comment

Chlorine is EXTREMELY HAZARDOUS, with an IDLH of 10 ppm and a TLV of 0.5 ppm (just above the odor threshold for most). Chlorine is heavier than air (VD > 2.5), and when released, it forms a greenish-yellow gas with a pungent, irritating odor that follows the terrain at ground level. The mean odor threshold for chlorine lies between 0.2 and 0.4 ppm. Chlorine is a NON-FLAMMABLE gas; however, it is a powerful oxidizing agent, reacting explosively or forming explosive compounds or mixtures with many common chemicals. Chlorine immediately reacts with both organic and inorganic materials it comes into contact with to form chlorides. The primary route of exposure is INHALATION. Chlorine is very volatile, with a Boiling Point of -29°F. So, although it is shipped as a liquidfied gas under pressure, once the primary containment is breached, it will quickly become a GAS. The Vapor Pressure of Cl2 is 6,450 mm hg @ STP. Remember, BP and VP have inverse relationships. As BP goes down, VP goes up, and vice versa. An excellent standard to follow is that water at STP has a VP of 25 mm hg and a BP of 212°F. Cl2 is the opposite: High VP (6,450 mm hg) and Low BP (-29°F).

Recently, a facility experienced firsthand why the IFC and its state fire code PROHIBIT the movement of hazardous materials via the facility's "tunnel system." The code does not prohibit the use of the tunnel system or even in enclosed corridors. Still, the design requirements for these tunnel systems or enclosed corridors to move HAZMATs are usually not cost-effective. Yet, many facilities do not post signs or include in their HAZMAT/HAZCOM training that these specific areas are "off limits" for transporting HAZMATs. Here is what the IFC and State Fire Code require: (emphasis by me and the revised structure is by me)

The battle continues, this time outside process safety! I get these arguments routinely when people inquire if they can use their HHC/EHS as the media for pressure and leak testing. I can only assume that PHMSA is getting pushback by requiring water or other similar viscosity liquid to be used as the test medium. When hydrostatic pressure tests for cargo tanks are required in part 180, subpart H, the HMR requires that water or other similar viscosity liquid be used as the test medium (see § 180.407(g)(viii)). PHMSA understands that some stakeholders believe the requirement to use water—or other similar viscosity liquid—may be unduly restrictive. PHMSA has authorized the use of alternate test mediums for portable tank testing (e.g., DOT SP–20294, 20308, and 16163), but has not authorized this for cargo tanks. PHMSA requests comment on the following questions to evaluate authorizing additional liquids for hydrostatic testing cargo tanks:

The 2024 edition of the International Fire Code has a new "table" that lists several exemptions. These exemptions come with some limitations, such as... Exempted materials and conditions listed in this table are required to comply with provisions of this code that are not based on exceeding maximum allowable quantities in Here are a few of the exemptions that may be of interest:

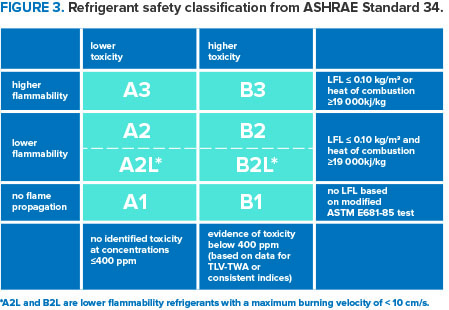

The refrigerant in this accident is R-32 (), described as " a colorless, odorless, mildly flammable gas. "Its ASHRAE rating is A2L, making it a CAT1B flammable gas if OSHA adopts Rev. 7 of the GHS this year. These A2L "mildly flammable gases" are exempt from many of the requirements other flammable gases must meet (e.g., electrical classifications, mechanical exhaust ventilation, gas detection, etc.).

|

Partner Organizations I am proud to announce that The Chlorine Institute and SAFTENG have extended our"Partners in Safety" agreement for another year (2024) CI Members, send me an e-mail to request your FREE SAFTENG membership

Member Associations

|