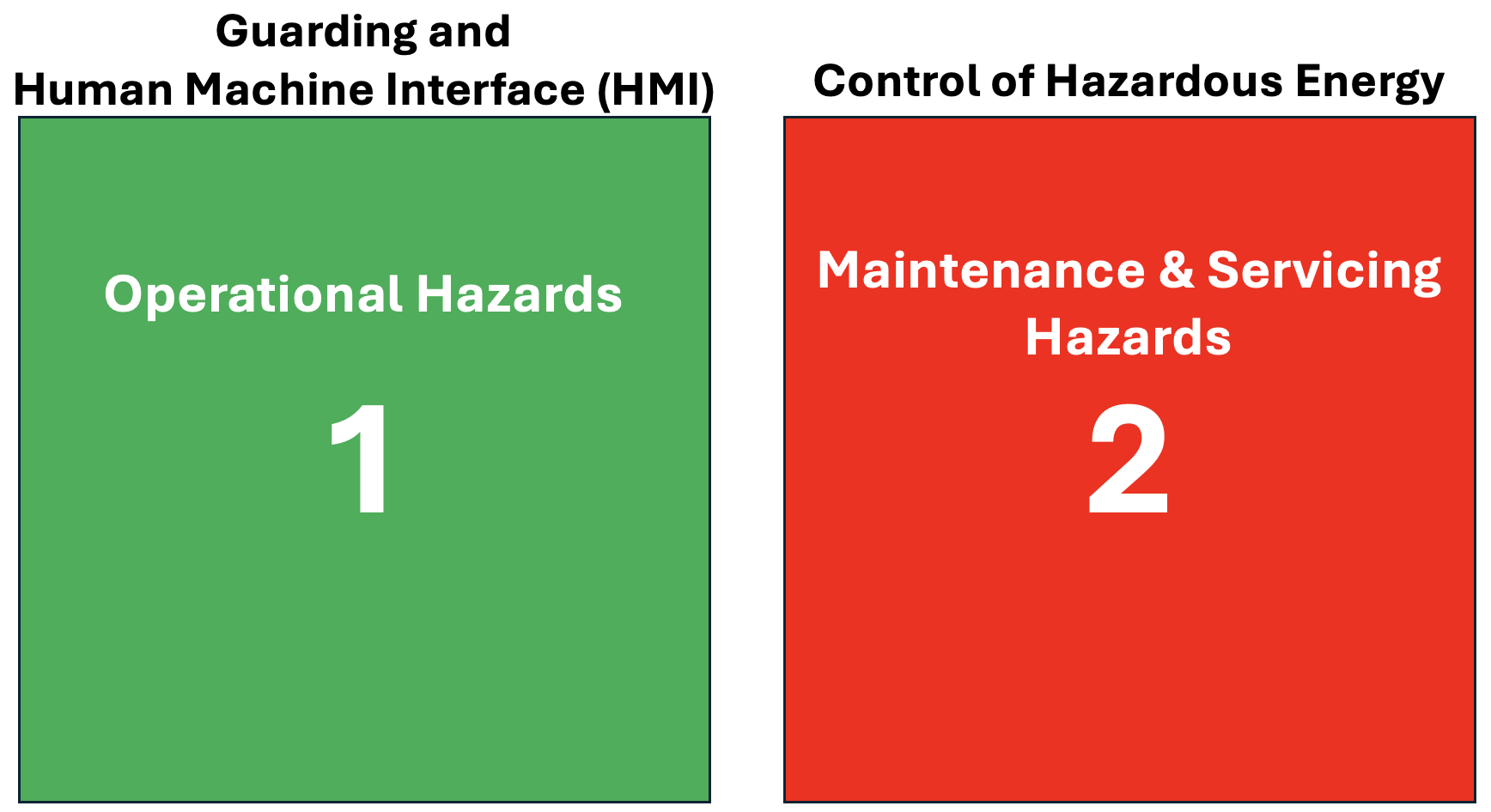

I put this image together for a friend struggling to demonstrate to their management that we can not discuss LOTO until Machine Guarding is in place. These two topics go hand in hand and trust me; if there are guarding issues, those hazards will be compounded when we attempt to frame up the LOTO program.

I put this image together for a friend struggling to demonstrate to their management that we can not discuss LOTO until Machine Guarding is in place. These two topics go hand in hand and trust me; if there are guarding issues, those hazards will be compounded when we attempt to frame up the LOTO program.

Guarding is for the OPERATIONAL safety of the machine/equipment and, if not done well, poses a big, if not bigger, risk to the workers running the machine/equipment. We routinely encounter serious guarding issues while helping clients with their LOTO efforts, and we are almost always told, "Thanks, but we just want help with LOTO."

Controlling hazardous energy sources (e.g., LOTO) during maintenance and servicing is just as critical but entirely different from guarding.

Just look at the scope/application of OSHA's 1910.147:

(emphasis by me)

|

1910.147(a)(2)(i) This standard applies to the control of energy during servicing and/or maintenance of machines and equipment.

1910.147(a)(2)(ii) Normal production operations are NOT covered by this standard (See subpart 0 of this part).

Servicing and/or maintenance which takes place during normal production operations is covered by this standard ONLY IF:

1910.147(a)(2)(ii)(A) An employee is required to remove or bypass a guard or other safety device; or

1910.147(a)(2)(ii)(B) An employee is required to place any part of his or her body into an area on a machine or piece of equipment where work is actually performed upon the material being processed (point of operation) or where an associated danger zone exists during a machine operating cycle.

|

We see this often; a poorly guarded machine rarely gets locked out for servicing/maintenance since the personnel doing the servicing/maintenance did not have to remove or bypass a guard or other safety device. The facility's LOTO program (and training) will usually use the exact wording from the standard to DEFINE when LOTO is required; so if the machine is NOT properly guarded, then the "trigger(s)" for LOTO are missing. Not to mention that the operations personnel are at serious risk of injury due to this improper guarding.