Safety Thought of the Week... Barrier/Controls/Safeguards Management

The purpose of barrier[/controls/safeguards] management is to make the kind of implicit controls explicit: to be clear about exactly

Source: Human Factors in Barrier Management, Prepared by a CIEHF Working Group comprising: Ron McLeod, Ian Randle, Rob Miles, Ian Hamilton, John Wilkinson, Christine Tomlinson, Gyuchan Thomas Jun, Tony Wynn. December 2016 Line Break gone bad (Cl2 cylinder change)

Eight people, including five (5) contract workers and three (3) fire service personnel, were admitted to the hospital after they inhaled chlorine gas following a leakage at a water treatment plant. Membership Content

EPA RMP citations @ chlorine, bleach, and hydrochloric acid facility (Cl2, H2, HCL & $264K w/ $363K SEP)

Respondent operated a facility (the “Facility”) to manufacture chlorine, bleach, and hydrochloric acid. Respondent produced, used, or stored more than 2,500 pounds of chlorine at the Facility and was subject to the requirements of CAA § 112(r)(7). Respondent produced, used, or stored hydrogen at the Facility and was subject to the requirements of CAA § 112(r)(1). Respondent was subject to Program 3 requirements because it had public receptors near the endpoint for the worst-case release and was subject to the OSHA process safety management standard set forth in 29 C.F.R. § 1910.119. Based upon the information gathered during the Investigation, EPA determined that Respondent violated certain provisions of the CAA. Differences between a H-2 and H-3 occupancy

In terms of Fire and Building Codes, we have five (5) recognized areas associated with handling hazardous materials. We refer to these high-hazard areas/occupancies as "Group H". High-hazard Group H occupancy includes, among others, the use of a building or structure, or a portion thereof, that involves the manufacturing, processing, generation or storage of materials that constitute a PHYSICAL or HEALTH HAZARD in quantities over those allowed in control areas complying with Section 5003.8.3, based on the maximum allowable quantity limits for control areas outlined in Tables 5003.1.1(1) and 5003.1.1(2). Hazardous occupancies are classified in Groups H-1, H-2, H-3, H-4 and H-5 and shall be in accordance with this code and the requirements of Section 415 of the International Building Code. Hazardous materials stored or used on top of roofs or canopies shall be classified as outdoor storage or use and shall comply with this code. H-1 buildings and structures contain materials that pose a detonation hazard, such as explosives. H-5 is specific to semiconductor fabrication facilities and comparable research and development areas. H-4 buildings and structures containing materials that are health hazards where materials such as Corrosives, Highly toxic materials, and Toxic materials are present. So that leaves us H-2 and H-3 areas, which, by me posting this under my Flammable Liquids category, you might have figured out that these two (2) hazardous occupancies are about flammable liquids and gases. But why have two (2) different ratings for the same hazard? "Normal venting" for aboveground tanks

During a recent design review, we encountered some questionable "normal breathing" designs. I have always used the simplest of tests to ensure the tank has ADEQUATE venting during filling and emptying. Although OSHA allows the designer to use API 2000 (1968) or "other accepted standards," the simplest test is that the VENTING capability MUST be as large as the filling or withdrawal connections, but in no case smaller than 1.25". However, unfortunately, designers fail to read ALL of .106(b)(2)(iv), which goes on to state: (emphasis by me) If any tank or pressure vessel has: Condensing water vapor creates a vacuum, destroys tank

Source: www.probrewer.com Implosion of ISO container during transfer (Vent valve NOT opened)

The implosion happened due to a vacuum created inside the tank when the MEG was pumped out into a storage reservoir on the vessel during mobilization. OSHA PSM citations @ Food plant (NH3 & $394K)

OSHA has again found a large food manufacturer with a history of hazardous workplace safety practices in violation of dozens of safety and health hazards. The producer of glass-pack, canned, frozen, refrigerated, freeze-dried, and snack food products under it's brand, as well as other private labels, also operates eight other manufacturing plants, including five in Pennsylvania and one each in Delaware, New Jersey, and Guatemala. In October 2023, CSHOs opened an investigation at the Centre Hall plant in response to a complaint alleging hazards involving the company’s handling of highly hazardous chemicals included in it’s Process Safety Management program. OSHA cited the company for 70 violations, including nine repeat, 51 serious, and 11 other-than-serious violations. The infractions related to numerous Process Safety Management failures, such as lack of training, not correcting equipment deficiencies, failing to document that equipment complied with recognized and generally accepted good engineering practices, and establishing an emergency plan for the entire plant. The agency has assessed the business with $761,876 in penalties. OSHA cited the company for similar violations at its Clayton, Delaware, facility in 2019 and 2021. When do I need to consider desinging and managing an area as a HAZLOC?

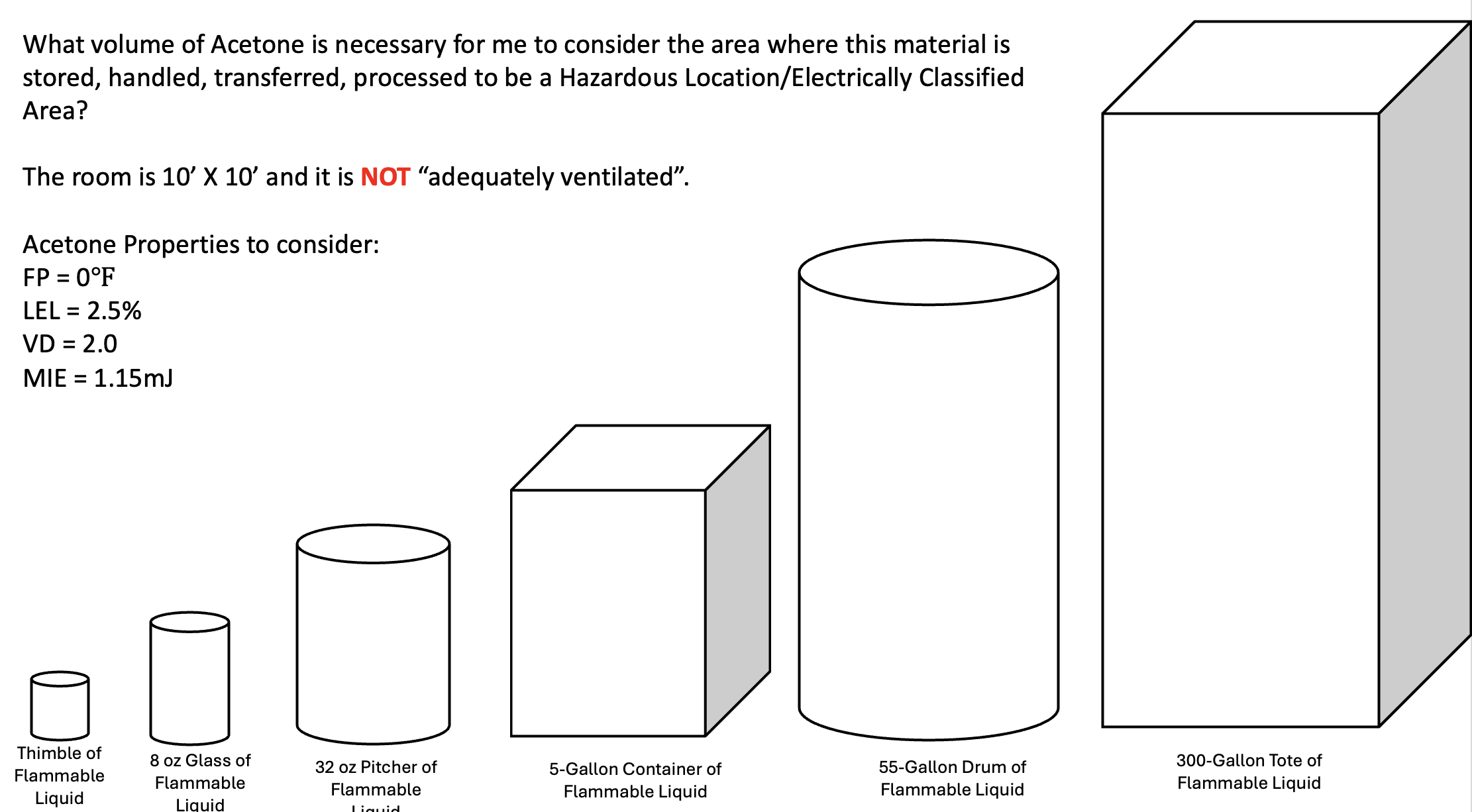

One mistake many businesses make is their assumptions about how their flammable liquids will behave once they are outside of their primary containment. I have seen companies spend millions of dollars to classify an area as a HAZLOC when it was not even close to being necessary, and I have seen some PSM businesses claim their 70,000-pound process does not need to be a HAZLOC. One of my advanced Flammable Liquids training course exercises is to help the students visualize the difference in the containers/containment involved in this risk analysis. Standing in the room, I hold up an old sewing thimble and ask, is this enough to make this room a HAZLOC? I then move to an 8-oz cup and ask. We go through the containers (as shown below), and as they work through the numbers in their head, we have great discussions about what we need to consider and how much we should weigh each point of consideration. They realize that the FP, the LEL, and the MIE all play a crucial role in understanding the ignition risks/hazards this flammable liquid or gas poses. Which container would you choose?

Just because you won't be working in a flammable atmopshere, it may still be TOXIC

I will again reference my 30 years of teaching emergency response courses and the surprising lack of hazard awareness so many "certified technicians" lack. The one that get a lot of attention is the relationship between TOXIC and PHYSICAL hazards when the HAZMAT is both toxic and flammable. I have shared many tips over the years, but the following is one that every safety professional should get tattoed onto their forearm: 1% = 10,000 ppm So, let's look at that relationship and think that we measure Lower Explosive Limits (LEL) in percentage and most often use ppm to measure inhalation hazards from vapors and gases. We can begin to see the relationship. This is a key relationship to understand when working in known hazardous atmospheres. We tend to focus on the acute risks when dealing with flammable liquids and gases: ignition of the vapor/gas and the consequences of that event. And YES, we need to be well aware of that hazard. But remember this: Most of the flammables we work around have LELs less than 5%; most are in the 2-3% range. Those percentages translate into the tens of thousands of parts per million (ppm). Take gasoline for example: Why does OSHA use 10% LEL to define a HAZ ATM within a PRCS?

One of the top questions I get via SAFTENG and in my PRCS or Hazardous Atmospheres training courses is... Why did OSHA use 10% LEL to define a hazardous atmosphere? There is an official and logical reason, both of which should be understood. First, the "official" reason: |

Partner Organizations I am proud to announce that The Chlorine Institute and SAFTENG have extended our"Partners in Safety" agreement for another year (2024) CI Members, send me an e-mail to request your FREE SAFTENG membership

Member Associations

|

"We were doing some cleaning at the end of yesterday. I boiled some water in the HLT to pump through the heat exchanger. At the end of the day, there were 40-50 gal left in our 3bbl HLT. I turned off the heat and went home for the night. The next morning, I came into the brewery to find an imploded HLT. I had clamped the lid on to keep humidity down in the building, and the cooling air/water in the HLT caused the tank to implode."

"We were doing some cleaning at the end of yesterday. I boiled some water in the HLT to pump through the heat exchanger. At the end of the day, there were 40-50 gal left in our 3bbl HLT. I turned off the heat and went home for the night. The next morning, I came into the brewery to find an imploded HLT. I had clamped the lid on to keep humidity down in the building, and the cooling air/water in the HLT caused the tank to implode." An ISO container, partly filled with Monoethylene Glycol (MEG), imploded on the back deck of a ship, spilling around two cubic meters (528 gallons) of MEG onto the deck and to sea and causing unrepairable damage to the tank itself. There were no injuries. The tank was a 26-cubic-meter tank containing ten cubic meters (6600 gallons) of MEG.

An ISO container, partly filled with Monoethylene Glycol (MEG), imploded on the back deck of a ship, spilling around two cubic meters (528 gallons) of MEG onto the deck and to sea and causing unrepairable damage to the tank itself. There were no injuries. The tank was a 26-cubic-meter tank containing ten cubic meters (6600 gallons) of MEG.